NHÔM THỎI

1. SẢN PHẨM: NHÔM BILLET 6063

Sản phẩm nhôm billet 6063 là sản phẩm nhôm thương mại phổ biến được xử lý nhiệt và pha trộn hợp kim sao cho phù hợp nhất để tạo ra các sản phẩm đùn ép được sử dụng trong ngành kiến trúc như khung cửa sổ, khung cửa đi, tấm lợp mái, trần… Nó được sản xuất với bề mặt nhẵn min, phù hợp cho các sản phẩm anot hóa nhôm. Sản phẩm billet được cắt theo chiều dài tùy theo từng yêu cầu của khách hàng.

2. TIÊU CHUẨN KỸ THUẬT:

Sản phẩm billet 6063 của của chúng tôi được pha nhiều loại hợp kim như sillicon, sắt, magie.... dựa theo tiêu chuẩn sản phẩm của Mỹ.Qua môi trường xử lý nhiệt, hợp kim 6063 có thể chống lại sự ăn mòn nói chung, bao gồm cả những ăn mòn từ vết nứt, nó dễ dàng được hàn hoặc uốn bằng nhiều phương pháp khác nhau.

Thành phần hợp kim, kích thước, chiều dài billet có thể được điều chỉnh tùy vào từng yêu cầu cụ thể của khách hàng.

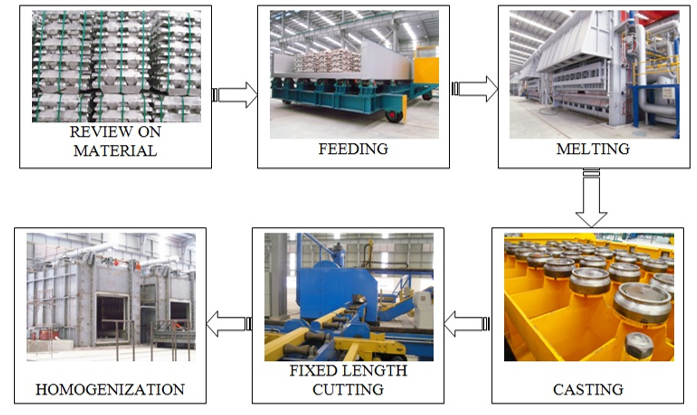

3. QUY TRÌNH SẢN XUẤT:

Quy trình của chúng tôi dựa trên tiêu chuẩn quản lý chất lượng trên từng bước sản xuất:

Kiểm tra nguyên liệu đầu vào:

Kiểm tra chất lượng và thành phần nguyên liệu thô (nhôm nguyên chất). Mỗi lô nguyên liệu Ingot được chọn mẫu ngẫu nhiên để kiểm tra hàm lượng trong phòng thí nghiệm trước khi chuyển sang tiếp liệu cho công đoạn nấu chảy và pha hợp kim.

Nấu chảy và pha hợp kim:

Một quá trình nấu chảy Ingot ở nhiệt độ 660 độ C, quy trình này, chuyển ingot từ thể rắn sang thể lỏng, biến chuyển tính chất vật lý nhôm nguyên chất và được pha các loại hợp kim (silicon, magie, nickel, đồng , sắt….) để tạo ra sản phẩm nhôm hợp kim phù hợp với từng yêu cầu sản xuất.

Đúc billet:

Nhôm hợp kim được đưa qua lò đúc và xử lý nhiệt để hạ nhiệt độ và chuyển sang thể rắn. Nhôm sẽ được kéo ra từng thanh dài theo kích thước và đường kính theo khuôn có sẵn.

Kiểm tra chất lượng bề mặt sản phẩm luôn được chú trọng trong công đoạn này.

Cắt billet thành phẩm:

Tùy theo từng yêu cầu cụ thể, billet sẽ được cắt theo nhu cầu của khách hàng. Chiều dài sản phẩm chuẩn của chúng tôi là 7,300 mm, sau khi cắt 2 đầu sẽ là 6,500mm, với những chiều dài bé hơn có thể dễ dàng điều chỉnh máy cắt cho phù hợp và cho ra những sản phẩm với kích thước đồng nhất để chuyển sang công đoạn xử lý kế tiếp.

Đồng nhất:

Sau khi được đúc thành thanh đúng với kích thước và đường kính yêu cầu, billet được chuyển sang lò xử lý đồng nhất. Được gia nhiệt trong thời gian nhất định để gia tăng các tính chất vật lý và hoàn thiện sản phẩm nhằm tạo ra những sản phẩm billet hoàn chỉnh, đồng nhất về chất lượng và bề mặt.

4. NGUỒN NGUYÊN LIỆU: NHÔM THỎI

Nguồn nguyên liệu của chúng tôi là nhôm nguyên chất (dạng thỏi), được nhập từ những nguồn tốt nhất trên thế giới (Úc, Nga, Dubai, Mỹ...)

Nhôm nguyên chất được lựa chọn kỹ lưỡng dựa vào thành phần, hàm lượng nhôm cũng như bề mặt hoàn thiện.